In most cases, you do not need to seal engineered wood flooring. The majority of engineered wood floors come factory sealed, with a protective finish already applied during manufacturing. Adding another seal on top is usually unnecessary and, in some situations, can even cause problems such as poor adhesion, trapped moisture, or premature finish failure.

However, this answer is not universal. Whether sealing makes sense depends on factors like the condition of the existing finish, foot traffic levels, exposure to moisture, and how the floor has been used over time. Some floors benefit from recoating or maintenance sealing, while others should never be sealed again.

In this guide, we explain:

- What “sealed” actually means for engineered wood flooring

- When sealing is helpful and when it is a mistake

- How sealing differs from recoating and refinishing

- and how to decide what your floor really needs, without guesswork

If you were looking for a quick answer, you already have it.

If you want to avoid damaging your floor or wasting money on unnecessary treatments, the sections below will help you make the right call.

Do You Need to Seal Engineered Wood Flooring?

Short Answer vs Real-World Use: In real-world conditions, sealing engineered wood flooring is rarely about adding protection and more about maintaining what already exists. Most engineered floors leave the factory with a durable finish designed to handle normal residential use without additional sealing. The confusion usually starts when wear becomes visible. Scratches, dull patches, or reduced water resistance often lead people to assume the floor needs sealing. In reality, these signs usually indicate finish wear, not a lack of seal.

Sealing only makes sense when the original finish has thinned evenly and the floor is compatible with recoating. In many other cases, sealing adds no benefit and can interfere with the existing factory finish.

The key difference is this: sealing is a maintenance decision, not a default requirement for engineered wood flooring.

Are Engineered Hardwood Floors Already Sealed?

Most engineered hardwood floors are already sealed before they are ever installed. This sealing is done at the factory, under controlled conditions, using finishes that are far more consistent and durable than anything applied on site. The confusion comes from how the word sealed is used. Many people assume sealing means adding an extra product after installation, when in reality the protection is usually built into the floor itself.

Factory-Applied Finishes Explained

Factory-sealed engineered wood flooring is finished using multiple coats of protective materials, most commonly polyurethane or UV-cured finishes. These layers are applied evenly and cured under heat or ultraviolet light, creating a hard, stable surface.

This factory process provides:

- consistent coverage across every board

- stronger resistance to wear than site-applied sealers

- protection against everyday spills and cleaning

Because of this, most engineered floors do not need additional sealing when they are new or properly maintained.

What “Sealed” Actually Means in Engineered Flooring

In engineered flooring, sealed does not mean waterproof or permanently protected. It means the wood surface is covered by a protective finish that slows moisture absorption and resists surface wear. This distinction matters. A sealed engineered floor can still be damaged by standing water, excessive moisture, or improper cleaning. Sealing reduces risk, but it does not eliminate it.

Understanding this difference explains why adding another sealant is often unnecessary and sometimes harmful. If the factory finish is intact, additional sealing usually does not improve performance and can interfere with how the floor was designed to function.

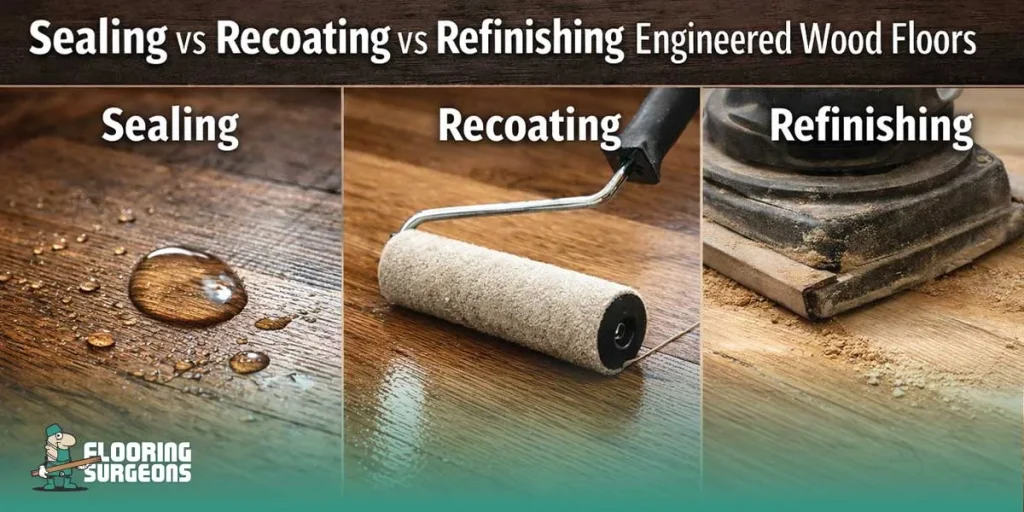

Sealing vs Recoating vs Refinishing Engineered Wood Floors

One of the biggest mistakes homeowners make is treating sealing, recoating, and refinishing as the same thing. They are not. Each process does something very different to engineered wood flooring, and choosing the wrong one can permanently damage the floor.

Comparison Table: What Each Option Really Does

| Method | What It Actually Involves | When It Makes Sense | When It Causes Problems |

| Sealing | Applying an additional protective layer over the existing finish | Rarely, and only on compatible finishes | Can trap moisture, cause adhesion failure, or void warranties |

| Recoating | Adding a new finish layer without sanding the wood | When the factory finish is worn but intact | Fails if the surface is contaminated or incompatible |

| Refinishing | Sanding and applying a new finish | Only on floors with sufficient wear layer thickness | Can permanently damage engineered floors |

- When Recoating Is Enough

Recoating is often the safest and most effective option when an engineered floor looks dull or lightly worn but is still structurally sound. It refreshes protection without removing wood material. This works only if the existing finish allows bonding and the surface is properly cleaned and prepared.

- When Sealing Is Unnecessary or Harmful

Sealing is unnecessary when the factory finish is intact. In some cases, adding a sealant on top of a factory-applied finish creates more problems than it solves. Incompatible products can peel, haze, or trap moisture beneath the surface, leading to finish failure rather than protection. This is where many well-meaning DIY attempts go wrong.

- Why Sanding Can Permanently Damage Engineered Floors

Unlike solid wood, engineered flooring has a limited wear layer. Sanding removes that layer quickly. Once it is compromised, the floor cannot be restored. Even light sanding done incorrectly can shorten the floor’s lifespan dramatically. This is the key difference competitors often overlook. Refinishing is not a reset button for engineered wood flooring. In many cases, it is a one-way decision. This risk is higher on floors with a thin engineered wood wear layer, because sanding can remove the protective surface much faster than most people expect.

The Key Takeaway: Most engineered wood floors do not fail because they were not sealed. They fail because the wrong maintenance method was chosen at the wrong time. Understanding the difference between sealing, recoating, and refinishing is more important than applying any product.

How Water-Resistant Is Engineered Wood Flooring Really?

Engineered wood flooring is often described as water-resistant, but that does not mean it is waterproof. Understanding this difference is critical because most damage happens when expectations do not match reality. This confusion often comes from assuming engineered wood is waterproof, when in reality, its engineered wood water resistance is limited.

Water-Resistant vs Waterproof

Engineered wood water resistance comes from its factory-applied finish and layered construction. The surface finish slows down moisture penetration, giving you time to clean up spills before damage occurs. Waterproof engineered hardwood flooring, however, does not truly exist in the way vinyl or tile can be waterproof. Water-resistant means delayed absorption, not immunity. If moisture is left sitting on the surface or seeps into joints and edges, damage can still occur.

Kitchens, Bathrooms, and Spills

In kitchens, engineered wood performs reasonably well when spills are cleaned quickly and humidity is controlled. Occasional splashes are not a problem, but standing water is. Bathrooms are a different story. High humidity, condensation, and frequent water exposure create conditions that exceed what engineered wood is designed to handle. Sealing does not change this risk in a meaningful way. Every day spills are rarely the issue. Long exposure, repeated moisture, and water trapped at seams are what cause swelling, cupping, or finish failure over time.

What Sealing Can and Cannot Protect Against

Sealing can help refresh surface protection when a compatible recoating is applied correctly. It can improve resistance to light moisture contact and reduce surface wear.

Sealing cannot:

- make engineered wood waterproof

- protect against standing water

- Stop moisture from entering through joints or edges

- prevent damage caused by high-humidity environments

This is why sealing should never be treated as a waterproofing solution. It is a maintenance step, not a moisture barrier.

Key Reality Check: If waterproof performance is required, engineered wood is often the wrong material, regardless of sealing. In those situations, alternatives like luxury vinyl or hybrid flooring are a more reliable choice.

When Should You Seal Engineered Wood Flooring?

Sealing engineered wood flooring should never be automatic. It only makes sense in specific situations where the existing factory finish has worn down evenly, and the floor is still structurally sound. The table below shows when sealing may help and when it is the wrong move.

Decision Table: Is Sealing the Right Choice?

| Scenario | Does Sealing Help? | Why | Better Option if Not |

| High-traffic areas | Sometimes | Foot traffic can thin the finish over time, reducing surface protection | Recoating if the finish is compatible |

| Homes with pets and kids | Rarely | Scratches and impact damage affect the wood, not just the finish | More durable flooring or protective mats |

| Older floors with worn finishes | Possibly | Even wear across the surface may allow a maintenance recoat | Professional assessment before any treatment |

Sealing can make sense only when:

- The wear is even, not patchy

- The factory finish is compatible with recoating

- The goal is maintenance, not damage repair

If scratches are deep, boards are swollen, or wear is uneven, sealing will not solve the problem and may make it worse. Sealing should be treated as a last maintenance step, not a first reaction. If you are unsure whether your floor qualifies, testing compatibility in a small, hidden area is far safer than sealing the entire floor.

When Sealing Engineered Wood Flooring Is a Bad Idea

Sealing engineered wood flooring can do more harm than good in several common situations. These risks are often overlooked, but they are some of the main reasons sealed floors fail prematurely.

- Factory finishes that should not be sealed over

Many engineered wood floors use UV-cured or aluminium oxide factory finishes. These surfaces are designed to resist adhesion. Applying sealers over them can lead to peeling, hazing, or uneven curing because the new product cannot bond properly. - Warranty and compatibility risks

Adding sealers or coatings not approved by the manufacturer can void warranties. Some finishes react chemically with sealants, causing discolouration or softening of the existing surface rather than added protection. - Moisture trapping and finish failure

Sealing over an incompatible or partially damaged finish can trap moisture beneath the surface. Instead of improving protection, this accelerates cupping, swelling, and finish breakdown, especially in areas with fluctuating humidity. - Floors with uneven or localised damage

Sealing does not fix scratches, dents, or worn patches. When damage is uneven, sealers highlight flaws rather than hiding them, making the floor look worse over time. - High-humidity environments

In spaces with persistent humidity, sealing can restrict natural moisture release. This imbalance increases internal stress within the boards and raises the risk of long-term structural issues.

Common Mistakes When Sealing Engineered Wood Floors

Most problems with sealed engineered wood floors are not caused by sealing itself, but by sealing being done at the wrong time or for the wrong reason. These are the most common mistakes that lead to disappointment or damage. In numerous instances, better results come from properly engineered wood floor cleaning rather than adding another sealant.

- Using the wrong sealant

Not all sealants are compatible with engineered wood flooring. Products designed for solid wood or generic surface sealers often fail to bond with factory-applied finishes. This results in peeling, hazing, or uneven curing rather than added protection. - Sealing floors that don’t need it

Many engineered wood floors are already factory sealed and performing as intended. Adding another seal in these cases does not improve durability and can interfere with how the original finish works, creating problems that did not previously exist. - Confusing shine with protection

A glossy or refreshed appearance does not always mean better protection. Shine is a visual effect, not a measure of durability. Some sealers improve appearance temporarily while offering little resistance to wear, moisture, or impact.

So, Is Sealing Engineered Wood Flooring Worth It?

In most cases, sealing engineered wood flooring is not necessary and often misunderstood. Modern engineered floors are designed to perform with their factory-applied finishes, and adding a sealant rarely improves durability. Sealing only makes sense in specific, limited scenarios, such as older floors with evenly worn finishes that are compatible with recoating. Even then, sealing should be treated as maintenance, not protection or repair. If the floor is new, structurally sound, or still performing well, sealing adds little value and can introduce avoidable risks. If the floor is damaged, unevenly worn, or exposed to moisture issues, sealing will not solve the underlying problem.

The practical rule is simple: engineered wood floors fail far more often from the wrong maintenance choice than from a lack of sealing. Sealing engineered wood flooring is a situational decision, not a default step. When in doubt, preserving the original factory finish or choosing proper maintenance is usually safer than adding another layer that the floor was never designed to handle. For tailored advice, speaking with Flooring Surgeons specialists can help avoid costly maintenance mistakes.