If you want the short, honest answer: laminate flooring should not be glued down in most UK homes — except in a few particular situations. Nearly all modern laminates are designed to be installed as a floating floor, and using the wrong adhesive can not only cause issues later but also void the warranty. Still, it may also void the manufacturer’s warranty. Still, there are cases where using glue — especially when you’re choosing the best glue for laminate flooring joints — can actually improve stability.

And this is precisely where many homeowners get confused. Some installers swear by a bit of glue to stop creaking, while others insist that glue-down laminate flooring is a terrible idea. Then you search online and find a mix of contradictory advice that leaves you with even more questions. If you’re renovating, installing a new floor yourself, or simply trying to make the right decision for a busy family home, wanting a clear, practical answer is entirely normal.

This guide gives you exactly that. Not just whether you should glue laminate, but when it helps, when it causes problems, which adhesives are suitable, and how each choice affects durability, noise, movement and long-term performance. If you’ve been looking for a straightforward, experience-based explanation — the kind that finally settles the debate — you’ve just found the guide that will make your decision significantly easier.

Table of contents

Glue Down Laminate Flooring — When It Makes Sense and When It Doesn’t

Glueing laminate flooring can make sense, but only in a few particular situations. Most of the time, a floating installation is the correct and safer option. Here’s the simple breakdown to help you decide quickly and confidently.

When glueing laminate flooring, does it make sense

There are a few cases where using glue is genuinely helpful:

- Tiny rooms

Tiny spaces like cupboards or narrow utility rooms can benefit from glue because the floor has less freedom to move. - Top steps of staircases

Laminate should never float on stairs. The nosing and the top step often need a glue-down installation for safety. - Areas where the floor shifts or creaks

Older homes with slightly uneven subfloors sometimes stop minor movement by glueing the joints. - Commercial spaces with constant foot traffic

Glue can add stability where people walk the same path all day.

These are “special cases”, not the rule.

When glueing laminate flooring is a bad idea

There are times when glue causes more problems than it solves:

- Large rooms

Laminate needs space to expand. Glueing it down prevents natural movement and causes buckling. - Over underlay

Laminate is designed to float on an underlay. Glue interferes with this and usually voids the warranty. - Over concrete that isn’t perfectly prepared

If the concrete is moist, the glue will fail—and the floor will lift. - Trying to stop the noise by glueing the whole floor

This backfires. The floor becomes louder because its cushioning layer is lost. - Any installation relying on click-lock joints for strength

Those planks are specifically engineered to float. Glue weakens the system instead of strengthening it.

If your room is normal-sized, flat, and uses click-lock planks, you should not glue down laminate flooring.

If your space is tiny, has stairs, or has a specific movement issue, glueing only the joints might help — but even then, it should be done carefully.

Can You Glue Laminate Flooring Joints? Pros, Cons & Proper Use Cases

If you’re wondering, “Can you glue laminate flooring joints?” the short answer is yes, but only in specific situations where it genuinely helps. Glueing every joint is not the standard installation method, and most laminate floors are designed to lock together without adhesive. But there are moments when adding a small amount of glue to the joints can solve problems that a floating floor alone cannot.

If your laminate joints keep shifting or opening even after installation, you can use a small amount of joint adhesive in problem areas. For a clear step-by-step guide on fixing separated joints without damaging the planks, see our practical guide on how to fill in gaps in laminate flooring.

When glueing laminate joints is actually useful

Glueing the joints can make sense in these cases:

- Rooms with unusual movement

If the floor flexes slightly due to an older subfloor, a touch of glue strengthens the locking system. - Very small or awkward-shaped spaces

In tight areas where planks can’t float freely, glued joints prevent shifting. - Moisture-prone doorways or transitions

A bit of glue in the joints can stop water from seeping between boards when used sparingly. - Floors that frequently separate at the seams

If click-lock joints keep opening, glue can stop the problem long-term.

Why do many installers avoid glueing laminate joints

Most professionals prefer not to glue joints for a few good reasons:

- Laminate is engineered to float

Glueing joints interferes with the natural expansion and contraction the floor needs. - Using the wrong glue can damage the click-lock system.

If it dries hard or brittle, the joints can crack under pressure. - Repairs become difficult

Floating planks are easy to lift and replace — glued ones are not. - Warranty issues

Many manufacturers clearly state that glued joints void their guarantees.

Common mistakes homeowners make

If someone uses glue when it’s not needed, these issues often appear:

- Planks buckle because they can’t expand

- The floor becomes noisy, especially near walls.

- Edges lift slightly due to trapped moisturiser.e

- Residue squeezes up through the joints and dries visibly.

These are the main reasons installers say “don’t glue unless you absolutely have to”.

The proper use cases — simple rule

Use glue only when:

- The room is small

- The floor shifts or separates

- You need a moisture-resistant joint in specific spots.

- A professional installer recommends it for your subfloor.

Avoid glue when:

- The room is large

- The subfloor is flat enough for floating.

- You plan to replace planks later.

- The manufacturer warns against

You can glue laminate flooring joints — but you shouldn’t do it by default. It’s a targeted solution for targeted problems. For a standard UK room with a click-lock system, floating installation is preferred. Glue becomes helpful only when you’re fixing movement, stabilising problem areas, or dealing with unusual layouts where floating isn’t enough.

Best Glue for Laminate Flooring Joints — What Installers Actually Use

Choosing the best glue for laminate flooring joints comes down to understanding how installers use adhesive in the real world. Laminate isn’t designed to be glued across an entire floor, so professionals rely on particular types of glue only when they need to reinforce the joints. The most common choice is a PVA-based laminate joint glue, a flexible adhesive that dries clear and remains slightly elastic. This elasticity matters because the laminate expands and contracts with temperature; a rigid glue would crack under that movement. Installers also prefer PVA because it wipes away cleanly during installation and doesn’t leave a visible film on the surface.

In small rooms or awkward layouts, professionals sometimes use D3-rated waterproof PVA glues, especially near kitchens, bathrooms, or doorways where spills are more likely. These glues create a moisture-resistant seal between planks, protecting the joints without stopping the floor from floating as a whole. What installers never use is wood glue, construction adhesive, or any solvent-based product. Those products dry too hard, damage the click-lock mechanism, and make future repairs nearly impossible.

Another thing homeowners often overlook is that the “best” glue isn’t the strongest one—it’s the one that supports the floor’s design. A high-strength adhesive sounds appealing, but if it stops the laminate from expanding, the boards will lift at the edges within months. This is the main reason installers apply glue sparingly, only to selected joints, usually in areas that show repeated separation or where water exposure is a concern.

A common mistake is assuming any PVA glue will do. Cheaper, craft-style PVAs become brittle over time and can trap moisture, which leads to swelling. Professional-grade laminate joint adhesives are explicitly formulated for click-lock systems and remain flexible for years. Another frequent error is applying too much glue. Excess adhesive squeezes to the surface, dries cloudy, and becomes almost impossible to remove without damaging the finish.

In practice, the best glue for laminate flooring joints is a clear, flexible, waterproof PVA explicitly made for laminate, used only when the installation truly benefits from it. Installers choose glue deliberately, not by habit: the goal is to support stability, protect joints from moisture, and address movement issues — without interfering with the floor’s ability to float. When used correctly, the right laminate joint glue strengthens the floor; when used in the wrong places, it can create more problems than it solves.

Do You Glue Laminate Flooring to Underlay? What Manufacturers Want You to Know

Laminate flooring should never be glued to the underlay — and manufacturers repeat this point more than any other installation rule. The whole system is engineered to “float”, meaning the boards sit on top of the underlay without being bonded to it. As soon as glue is introduced between the laminate and underlay, the floor loses its ability to expand and contract freely. That small change is enough to cause lifting, creaking, edge tension and, in many cases, complete installation failure within the first year. This is why nearly every major brand states clearly that glueing laminate to underlay immediately voids the warranty.

The underlay itself is designed to do all the work that glue cannot: it absorbs footsteps, evens out minor imperfections and provides a moisture barrier when required. If you glue laminate to underlay, you freeze the floor in place and prevent the underlay from doing its job. Instead of cushioning movement, the adhesive locks the entire system rigid, creating pressure points that slowly telegraph through the click joints. These stresses don’t show up on day one — they appear gradually as tiny gaps, bowed planks or hollow-sounding patches that are incredibly difficult to fix.

There are, however, a few narrow exceptions that confuse homeowners. Some commercial glue-down vinyl products, or early 2000s laminate systems, were designed for direct adhesion. Modern laminate flooring is not. Even in professional environments where extra stability is required, installers never glue laminate to underlay; they switch to flooring that is actually engineered for glue-down use. If the project requires no movement, laminate isn’t the right material.

Manufacturers also highlight the moisture-related risks. A glued layer traps condensation between the laminate and the underlay, especially on concrete subfloors. Over time, that hidden moisture can cause swelling from underneath — a type of damage that cannot be sanded, repaired or replaced plank-by-plank. Because this failure stems from incorrect installation, warranties are automatically rejected, regardless of the flooring’s quality.

In short, the message from manufacturers is simple: laminate and underlay are partners, but they must remain separate. The underlay supports the floor; the laminate floats on top. Glue creates a bond that the system was never designed to handle, turning a flexible installation into a rigid one that will eventually fail. If stability, sound reduction or moisture control is your concern, the answer isn’t glue — it’s choosing the right underlay and installing the laminate exactly as the manufacturer intended. For anyone who wants deeper guidance on making the installation last, resources from flooring surgeons are often a helpful reference point, especially when comparing different underlay types and performance levels.

Can You Glue Laminate Flooring to a Concrete Floor? Essential Rules Before You Start

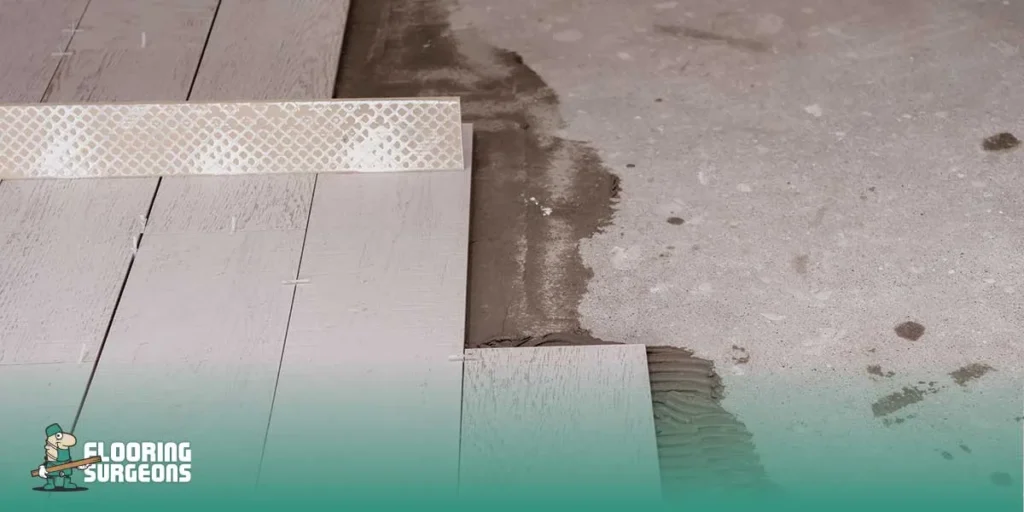

You can glue laminate flooring directly to a concrete floor, but only if the concrete is dry, stable and fully prepared — and this is where most installations fail. Laminate isn’t designed for glue-down use, so if you’re planning to bond it to concrete, every step must be done precisely to avoid swelling, edge tension, or early delamination. Think of concrete as the foundation that decides whether the floor survives or becomes a warranty nightmare.

The first non-negotiable rule is moisture testing. Concrete holds water far longer than people expect, and even “old” slabs can keep releasing vapour for years. If the subfloor exceeds the manufacturer’s moisture limit — usually measured with a CM test or a digital moisture meter — the glue-down method becomes risky from the start. Ignoring this step is the number one reason glued laminate on concrete begins to cup or lift within months.

If moisture levels pass the test, the next essential layer is a primer or moisture barrier designed for glue-down installations. This isn’t the same as an underlay, and it isn’t optional. Primers seal fine dust in the concrete, strengthen the surface and help the adhesive bond evenly. Without a proper primer, the glue sticks to dust rather than the concrete, and the entire floor loses adhesion in patches.

Choosing a compatible adhesive is equally essential. Only certain flexible flooring adhesives are suitable for laminate, and even then, manufacturers rarely guarantee the results. A rigid glue can harden the plank and stop it from expanding, while a soft glue allows too much movement, creating hollow spots. The best-performing adhesives for laminate-on-concrete tend to be polymer or hybrid formulations that retain some elasticity. Still, you must always check the flooring brand’s own compatibility list before applying anything.

Concrete installation also has its own set of common mistakes that quickly ruin the project. Skipping surface levelling means the glue won’t spread evenly, creating tension points that can cause the planks to crack or shift. Bonding laminate to a cold concrete slab can cause condensation under the boards, especially in basements or ground-floor spaces. And applying too much adhesive might feel “stronger”, but it actually limits the plank’s ability to move naturally with temperature changes.

In short, glueing laminate to concrete is possible, but it demands far more planning than a standard floating installation. If moisture is controlled, the primer is correct, and the adhesive is chosen explicitly for laminate, the method can work in specific spaces. If any of those steps are rushed or ignored, the floor will eventually fail — even if it looks fine on day one. For homeowners who want a long-lasting result, success isn’t about the glue itself but about respecting the rules the concrete sets for you.

How to Plan a Glue-Down Laminate Installation the Right Way

Planning a glue-down laminate installation is all about strategy — not speed. If the layout, acclimation and expansion gaps aren’t planned correctly from day one, even the best adhesive won’t save the floor from lifting or tightening later. A glue-down install requires precision, and the planning stage is where it begins. Below is the cleanest, simplest UK-friendly roadmap you can follow, without repeating any of the technical points covered in earlier sections.

1) Plan Your Layout Before Opening a Single Box

A glue-down installation has no room for guesswork. The layout must be locked in before you even unpack the planks.

• Map the room — Identify the longest, straightest wall and use it as your reference line.

• Avoid thin cuts — Shift your layout so the first and last rows are wider than 5–6 cm (thin strips lift faster).

• Check doorways & transitions — Plan where each plank falls so transitions don’t look forced or uneven.

• Dry-lay the first few rows — This solves 90% of alignment issues before glue ever touches the floor.

2) Acclimate the Laminate Properly (Non-Negotiable)

Glue-down laminate reacts more to environmental changes than floating floors, so the planks must fully acclimate to the room.

• Acclimate for 48–72 hours at normal living temperature (18–25°C).

• Leave the boxes open so air reaches the planks evenly.

• Keep the room stable — No heaters, no cold drafts, no sudden humidity spikes.

This simple step prevents tension lines, micro-gaps and edge pressure once the boards bond to the subfloor.

3) Expansion Gaps Are Still Required — Even with Glue

A big misconception: “If I glue laminate, I don’t need expansion gaps.”

Wrong. Expansion gaps are even more critical because the planks cannot float freely once bonded.

• Leave 8–12 mm around all walls, pillars and fixed objects.

• Use spacers during installation to keep lines perfect.

• Add movement breakpoints in rooms longer than ~10 metres.

Skipping expansion gaps is guaranteed to cause buckling, especially in UK homes with seasonal humidity swings.

4) Ensure You Have All the Tools Before You Start

A glue-down installation can get messy fast if you stop halfway to look for missing tools. Prepare everything in advance.

• Trowel with the adhesive’s recommended notch size

• Pull bar + tapping block for tight joints without damaging the edges

• Spacers for consistent expansion gaps

• Rubber mallet for settling planks without impact marks

• Moisture-resistant pencil + straightedge for accurate cuts

• Clean microfibre cloths to remove excess adhesive instantly (dried glue ruins the finish)

Being fully equipped makes the entire process cleaner, faster and far more accurate.

5) Plan Your Working Pace — Glue Has a Time Window

Glue doesn’t wait for mistakes. Once it’s on the floor, you must keep moving.

• Plan in small sections, usually 1–1.5 m at a time.

• Know your open time — most adhesives stay workable for 20–40 minutes.

• Have an exit route — you don’t want to glue yourself into a corner.

Good planning avoids rushed decisions, crooked boards and messy adhesive lines.

6) Pre-Check All Planks Before They Touch Glue

Glue-down installations expose imperfections more clearly than floating floors.

• Check for bowed planks

• Sort out colour variations

• Use the straightest pieces for your first row

This gives you a crisp, professional-looking finish that doesn’t need correcting later.

7) Final Planning Check Before Installation

A quick, 30-second checklist that saves you hours of fixing mistakes later:

• Is the room acclimated and stable?

• Are the expansion gaps marked and ready?

• Is the layout mapped with no thin cuts?

• Are all tools prepared and within reach?

• Do you have a clear working direction and exit plan?

If all answers are “yes”, you’re ready to start the glue-down installation with confidence.

How to Remove Glued Laminate Flooring Without Damaging the Subfloor

Removing glued laminate flooring requires a slower, more controlled approach than lifting a floating floor, and the key to protecting the subfloor is letting the adhesive release gradually rather than forcing the boards up. The safest way to start is by softening the glue with a heat gun or flooring heat plate. A short burst of heat loosens the adhesive just enough for the plank to move without tearing the surface underneath. Trying to pry the planks cold is the main reason concrete gets chipped or timber subfloors lose fibres.

Once the glue begins to soften, lift each plank slowly using a wide putty knife or a thin pry bar, easing the tool under the board bit by bit. Small sections are always safer than long pulls; if any part resists, stopping and reheating is far better than pushing through it. Working in a calm, deliberate rhythm prevents the board from snapping and keeps the adhesive from ripping away chunks of the subfloor.

After the planks are up, the remaining adhesive needs to be cleaned carefully. Warm small areas at a time and scrape lightly, repeating the process until the surface is smooth. Concrete can tolerate slightly firmer scraping, but timber subfloors require gentler pressure to avoid scarring. Rushing this stage is one of the fastest ways to create uneven spots that later affect new flooring installations.

Throughout the process, ventilation and fundamental safety matter. Heating old adhesive can release mild fumes, and lifting boards often creates dust, so open windows and use gloves and a mask to stay protected. Above all, avoid using solvents unless you are sure they are safe for the subfloor, and never try to pull up the planks by force. Glue-down laminate rewards patience; when you work slowly and let the adhesive release naturally, the subfloor stays intact and ready for whatever flooring you plan to install next.

Floating Laminate vs Glue-Down Laminate — Which Installation Method Is Easier?

If your primary concern is ease of installation, the floating method is almost always the simpler, more beginner-friendly option. Floating laminate is designed to click together without adhesives, tools are minimal, and most DIY homeowners can complete an average-sized room in a single afternoon. Because the boards sit on top of the underlay rather than bonding to the subfloor, there’s more room for minor errors, adjustments, and repositioning during the installation. Even if you misalign a plank or want to redo a section, you can unlock the joints and start again without damaging the floor.

Glue-down laminate, by comparison, demands more precision and significantly more preparation. Once adhesive is applied, the working time is limited: you must position planks accurately before the glue begins to set, and any mistakes are much harder to undo. The process is slower, stickier, and requires consistent pressure across the boards to ensure an even bond. It’s not necessarily complicated, but it is unforgiving — which is why professionals tend to favour the glue-down method only when conditions or room design genuinely require it.

For most homeowners deciding between the two, the difference is clear. Floating laminate offers speed, flexibility and low stress. Glue-down laminate offers stability, but only at the cost of greater effort, stricter planning and essentially no room for error. If your priority is a straightforward installation, the floating method wins every time.

Does Glueing Laminate Flooring Void the Warranty? Manufacturer Guidelines Explained

Whether glueing laminate flooring voids the warranty depends almost entirely on what the manufacturer specifies — and this is where many homeowners get caught out. Most modern laminate products are engineered specifically for floating installation, and manufacturers make this very clear in their documentation. In these cases, applying glue directly to the underlay or subfloor almost always voids the warranty because it interferes with the product’s design, affects movement allowance and increases the risk of structural damage over time.

Glueing the joints, however, is treated differently. Some manufacturers allow a small amount of joint adhesive to reinforce locking systems in bathrooms, hallways or areas with heavier traffic. Others explicitly advise against any adhesive, even at the edges, because their locking mechanisms perform best when left untouched. Calling the brand’s helpline or reading their technical sheet is the only reliable way to know which category your product falls into.

The crucial point is this: laminate warranties are strict because the material behaves predictably only when installed exactly as intended. A glue-down installation might feel more secure, but if the brand forbids adhesives, any future problems — from swelling to buckling — will be considered installer error. Before opening the first bottle of glue, always check the manufacturer’s fitting guide. It’s a two-minute step that protects not only your flooring investment but also your right to claim support if something goes wrong later.