Terrazzo flooring is made from decorative aggregates such as marble, quartz, granite, or glass chips that are embedded in a binder, most commonly cement or epoxy resin. Once the mixture cures, the surface is ground and polished to create a smooth, durable finish with a distinctive speckled appearance.

The exact feel and performance of terrazzo depend on what it is made of. Cement-based terrazzo is typically thicker and has a more traditional character, while epoxy-based terrazzo is thinner, offers sharper colour options, and is often used where a more seamless, precise finish is needed. Aggregate size, binder type, and any additives all influence the final look, slip resistance, and maintenance needs.

If you are researching terrazzo for a home or commercial space, understanding these core ingredients helps you ask the right questions before installation. As flooring specialists at Flooring Surgeons, we look at the full build-up, the environment, and the intended use of the space to help ensure the terrazzo system you choose delivers both the look you want and the performance you need. For specialist guidance on choosing and specifying the right flooring system, visit Flooring Surgeons.

Table of contents

The Core Components of Terrazzo Flooring

Understanding what terrazzo flooring is made of requires breaking it down into three structural layers: the decorative aggregates, the binder system that holds them together, and the supporting additives that influence performance and longevity.

What Are Terrazzo Chips Made Of? Understanding Decorative Aggregates

Terrazzo aggregates are the visible chips that give the floor its distinctive speckled appearance. These chips can be made from several natural or manufactured materials, each affecting colour variation, durability, and overall character.

Common terrazzo aggregates include:

- Marble chips

The most traditional material used in terrazzo flooring composition is. Marble offers soft veining and a classic aesthetic often associated with historic buildings. - Granite chips

Harder and more durable than marble. Granite provides a denser surface and stronger resistance to abrasion. - Quartz

Highly durable and consistent in tone. Quartz aggregates are often used where performance and scratch resistance are priorities. - Glass chips

Used in modern terrazzo systems to introduce brighter colours and reflective qualities. - Recycled materials

Crushed porcelain, recycled glass, and reclaimed stone are increasingly used in sustainable terrazzo flooring systems.

How Chip Size Affects Terrazzo Appearance

The size of terrazzo chips significantly impacts the final look.

- Smaller aggregates create a more uniform, subtle finish.

- Larger chips produce a bold, graphic appearance with stronger visual movement.

Chip size and distribution act like a visual pattern, and how floor patterns guide eye movement explains why some layouts feel calmer while others feel more energetic. Designers and installers adjust chip size depending on whether the goal is minimal refinement or expressive pattern contrast.

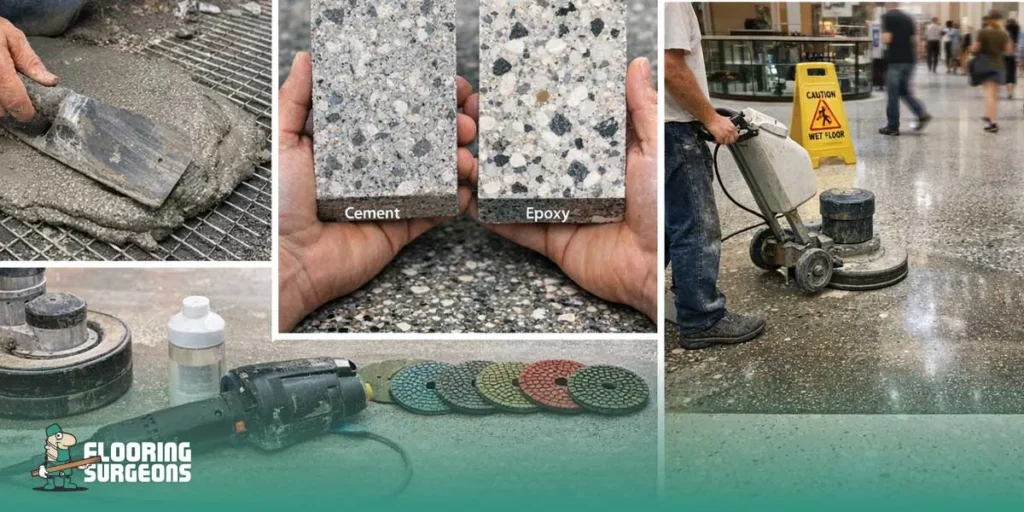

Terrazzo Binder Types Explained: Cement-Based vs Epoxy Systems

The binder is the material that holds terrazzo aggregates together. It determines flexibility, thickness, curing time, and overall performance. There are two primary binder types used in terrazzo flooring construction:

Cement-Based Terrazzo

This system uses Portland cement as the binding material. Cement undergoes hydration, meaning it hardens through a chemical reaction with water. Cement-based terrazzo is typically thicker and has a more traditional appearance. It is often used in large commercial installations.

Epoxy-Based Terrazzo

This system uses resin as a binder. Epoxy cures through a chemical reaction between resin and hardener rather than hydration. The result is a thinner, more flexible flooring system that allows for brighter pigments and sharper aggregate contrast. Epoxy terrazzo is common in interior environments where precision and colour clarity are important. The choice between cement and epoxy affects crack resistance, installation method, curing time, and structural build-up. Because epoxy terrazzo uses a resin binder, it helps to understand how polymer flooring systems behave in real interiors.

Structural Additives and Reinforcements in Terrazzo Flooring Systems

Beyond aggregates and binder, terrazzo flooring includes additional components that enhance stability, design control, and long-term performance.

These may include:

- Pigments

Added to the binder to control background colour and design consistency. - Metal divider strips

Thin strips are placed between sections to control cracking and define patterns. - Sealers

Applied after polishing to protect the surface from staining and moisture penetration. - Moisture barriers

Installed beneath the terrazzo system to prevent subfloor moisture from affecting adhesion. - Reinforcement mesh

Used in cement-based systems to reduce the risk of structural cracking.

These supporting materials are often overlooked when asking what terrazzo flooring is made of, but they play a critical role in how the finished surface performs over time.

Cement Terrazzo vs Epoxy Terrazzo: What Is the Difference?

When asking what terrazzo flooring is made of, the most important distinction is the binder system. The choice between cement terrazzo and epoxy terrazzo affects thickness, flexibility, curing time, crack resistance, and overall suitability for different environments. Both systems use decorative aggregates, but the material that binds those aggregates together changes how the flooring performs over time.

Cement-Based Terrazzo

Cement terrazzo uses Portland cement as its binder. It hardens through hydration, meaning a chemical reaction occurs when cement mixes with water. This traditional system is typically thicker and often installed over a reinforced base. Because it relies on cement curing, installation time is longer, and environmental conditions must be carefully controlled. Cement terrazzo is commonly used in large commercial or institutional spaces where structural depth is not a limitation.

Epoxy terrazzo

Epoxy terrazzo uses a resin system as its binder. It cures through a chemical reaction between resin and hardener rather than hydration. This allows for a thinner application, faster curing time, and greater design flexibility. Epoxy systems also allow for more vibrant pigments and sharper aggregate definition. Epoxy terrazzo is widely used in interior applications where precision and reduced floor thickness are important. If you like seamless, low-maintenance surfaces but want to compare alternative resilient options, explore luxury vinyl flooring (LVT) for interior-friendly solutions.

The Difference Between Cement Terrazzo and Epoxy Terrazzo

| Feature | Cement Terrazzo | Epoxy Terrazzo |

| Binder Type | Portland cement | Epoxy resin |

| Thickness | Thicker | Thinner |

| Flexibility | Low | Higher |

| Installation Time | Longer cure | Faster cure |

| Crack Resistance | Moderate | Higher |

| Suitable For | Large commercial spaces | Interior applications |

If you are also weighing terrazzo against other surfaces, see is terrazzo flooring expensive for a separate guide focused on value and long-term ownership. Understanding this difference is essential when evaluating terrazzo flooring composition. The binder system directly influences performance, structural requirements, and long-term durability. For flooring specialists, selecting the right terrazzo system begins with assessing the building structure, subfloor conditions, and intended use of the space.

How Terrazzo Flooring Is Constructed

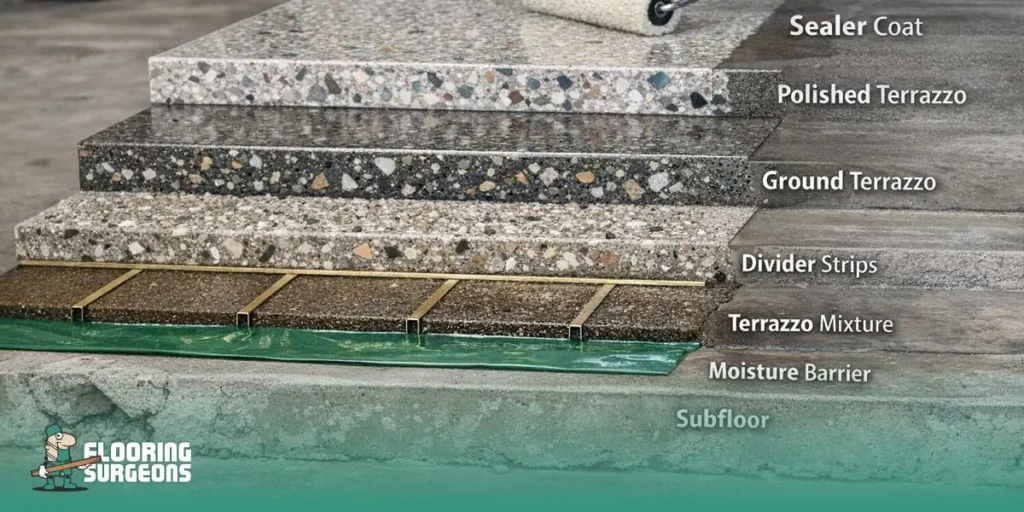

Understanding what terrazzo flooring is made of is only part of the picture. To evaluate its durability and long-term performance, it is equally important to understand how the full system is constructed. Terrazzo is not simply poured and polished. It is built in layers, each of which plays a structural role. Below is a simplified technical overview of a standard terrazzo floor build-up.

- Subfloor preparation

The structural base must be clean, level, and stable. Any cracks, movement, or moisture issues in the concrete slab are addressed before installation begins. Surface profiling may be required to ensure proper adhesion of the terrazzo system. - Moisture barrier

A moisture barrier or damp-proof membrane is installed if required. This prevents rising moisture from the subfloor from affecting the bond between the terrazzo binder and the base. Moisture control is critical for long-term performance, particularly in cement-based systems. Moisture testing and the right barrier matter more than most people expect, and this guide explains when you need a damp-proof membrane under your floor. - Divider strips installation

Metal divider strips are positioned across the surface. These strips serve two purposes. They control cracking by dividing the floor into sections, and they define design patterns or transitions. Proper placement ensures structural stability and visual precision. - Terrazzo mixture application

The terrazzo mixture, composed of aggregates and binder, is mixed and poured or trowelled onto the prepared surface. Thickness depends on whether the system is cement-based or epoxy-based. The material is then compacted to remove air pockets and ensure uniform density. - Initial curing phase

The binder begins its curing process. Cement systems harden through hydration, while epoxy systems cure through chemical reaction. Adequate curing time is essential before mechanical grinding begins. - Grinding process

Once cured, the surface is mechanically ground using progressively finer abrasives. This exposes the decorative aggregates and levels the floor to a uniform plane. Grinding determines how prominently the chips appear in the final finish. - Polishing

After grinding, the surface is polished to achieve the desired sheen level. The degree of polish affects reflectivity, texture, and maintenance characteristics. - Sealing

A penetrating sealer is applied to protect the terrazzo surface from staining and moisture penetration. Sealing enhances longevity and simplifies maintenance without altering the structural integrity of the floor.

Each stage of this buildup influences the final durability, crack resistance, and visual clarity of terrazzo flooring. Proper installation is not just about aesthetics. It is about ensuring that the structural layers beneath the polished surface perform reliably over time.

Why Material Composition Affects Terrazzo Flooring Performance

Terrazzo flooring performance is directly shaped by what it is made of. The type of aggregates, the binder system, and the installation structure all influence how the floor behaves over time.

Durability depends on aggregate hardness and binder strength.

Granite and quartz chips resist abrasion better than softer marble. Epoxy binders generally provide stronger adhesion, while cement systems rely more on thickness and reinforcement.

Crack resistance is linked to flexibility.

Cement-based terrazzo is less flexible and may require reinforcement mesh or expansion joints. Epoxy terrazzo offers greater flexibility, which can reduce cracking in interior applications.

Moisture tolerance varies between systems.

Cement terrazzo is breathable but must be properly sealed. Epoxy terrazzo becomes non-porous once cured, improving resistance to staining and moisture penetration. This difference is especially important in kitchens and high-humidity areas.

Maintenance requirements are influenced by density and sealing.

A well-polished and sealed terrazzo surface is relatively low-maintenance. Regular cleaning and occasional resealing help preserve performance.

Longevity is one of terrazzo’s strongest advantages.

Because aggregates run through the topping layer, the surface can be refinished multiple times. With proper installation, terrazzo can last for decades.

Suitability for commercial or residential use depends on structure and traffic levels.

Cement terrazzo is often used in large commercial spaces. Epoxy terrazzo is commonly selected for residential and retail interiors where thinner systems and sharper colour definition are preferred.

For flooring professionals, understanding terrazzo flooring composition is not theoretical. It guides subfloor preparation, system selection, and long-term durability planning. Material knowledge is what turns a decorative surface into a structurally reliable floor.

Is Terrazzo Flooring Sustainable?

Sustainability is increasingly part of the conversation when evaluating what terrazzo flooring is made of. The environmental impact of terrazzo depends on both the aggregates used and the binder system selected. One sustainability advantage is the use of recycled aggregates. Many terrazzo systems incorporate recycled glass, reclaimed stone, or crushed porcelain. This reduces reliance on newly quarried materials and diverts waste from landfill.

Longevity also contributes to sustainability. Terrazzo floors can last several decades with proper maintenance. Because they can be refinished rather than replaced, they reduce the material waste associated with short lifecycle flooring options. However, the environmental profile differs between binder systems. Cement-based terrazzo contains Portland cement, which has a significant carbon footprint due to energy-intensive manufacturing processes. Epoxy-based terrazzo relies on synthetic resin systems derived from petrochemicals. While epoxy systems may require less material thickness, their production also carries environmental considerations.

Evaluating sustainability, therefore,e requires a balanced perspective. Recycled content, lifecycle durability, installation method, and maintenance practices all play a role. For clients focused on environmental performance, careful material selection and proper installation are essential to ensuring terrazzo aligns with broader sustainability goals.

Conclusion

Terrazzo flooring is made from decorative aggregates embedded in a binder system, then ground, polished, and sealed to create a durable surface. In simple terms, terrazzo equals aggregates plus binder plus a precision polishing process. The specific composition determines how the floor performs. Aggregate type influences durability and appearance, while the choice between cement and epoxy affects flexibility, thickness, moisture tolerance, and long-term maintenance.

Because terrazzo is a layered system rather than a simple surface covering, expert installation is essential to ensure structural stability and lasting performance. Material knowledge, subfloor assessment, and correct curing all play critical roles. If you are considering terrazzo for a residential or commercial project, explore expert terrazzo and specialist flooring guidance at Flooring Surgeons.