Yes, laminate flooring should be staggered in most installations, and it is not a decorative choice. Staggering is necessary to keep the joints aligned correctly and to distribute weight evenly across the floor, which helps prevent movement, noise, and long-term failure. Simply offsetting boards at random or using very short stagger distances is not acceptable and can weaken the click system rather than support it. If the joints line up too closely, pressure concentrates in the same areas, increasing the risk of gaps, clicking sounds, and joint damage over time. In most cases, laminate flooring systems rely on correct joint spacing to maintain structural stability over time.

This is why most manufacturers and experienced installers treat staggering as a structural requirement, not a preference. The details matter, though. How much stagger is enough, why some common patterns cause problems, and where installations usually go wrong are what determine whether a laminate floor performs properly or starts failing earlier than expected.

Table of contents

Why Staggering Laminate Flooring Matters

Staggering laminate flooring is about how the floor behaves under load, not how it looks. When boards are offset correctly, forces from foot traffic are spread across multiple joints instead of concentrating in one line. This reduces stress on the locking mechanism and helps the floor move as a single, stable surface rather than a series of weak points.

- Structural Stability of Click Systems

Click systems are designed to distribute weight sideways and lengthwise through the joints. Proper staggering allows each board to support its neighbours, sharing load across the floor. When joints are offset, pressure from walking or furniture is absorbed gradually and released evenly.

Problems begin when joints line up too closely. Repeated end joints create a straight stress path through the floor, which weakens the locking edges. Over time, this concentrated load can cause the clicks to loosen, especially in high-traffic areas. The result is a floor that looks fine at first but lacks long-term structural support.

- Preventing Movement, Gaps, and Failure

Incorrect staggering often leads to small movements that become noticeable with use. Boards may flex slightly underfoot, creating clicking sounds as joints shift against each other. These movements are not random; they happen where pressure is focused around poorly staggered joints.

As stress continues to build in the same spots, gaps can begin to open at the ends of boards. This is not a surface issue but a sign that the load is not being distributed correctly. Point pressure increases wear on the locking system, which can eventually lead to joint failure and sections of flooring needing replacement. Proper staggering reduces these risks by keeping movement controlled and evenly spread across the floor.

What Happens If Laminate Flooring Is Not Staggered Properly

When laminate flooring is not staggered correctly, the problems usually appear gradually rather than all at once. What starts as a minor annoyance can turn into structural damage that is difficult to fix without removing large sections of the floor.

- Noticeable noise underfoot. Poorly staggered joints shift under pressure, creating clicking or tapping sounds as boards move against each other.

- Movement when walking across the floor. Concentrated joints allow boards to flex more than intended, which can be felt as slight movement in specific areas.

- Progressive weakening of the click system. Repeated stress along aligned joints puts excessive strain on the locking edges, causing them to loosen over time.

- Gaps are opening between boards. As the locking system degrades, end joints can begin to separate, especially in high-traffic zones.

- Widespread flooring failure. Once the joints are compromised, repairs often require lifting and replacing large sections of the floor rather than isolated boards.

How Much Stagger Is Actually Required

Getting the stagger distance wrong is one of the most common reasons laminate floors fail early. The goal is not variation for its own sake, but keeping enough distance between joints to avoid concentrated stress. Board durability also plays a role, which is why the AC rating of laminate flooring should be considered alongside correct joint spacing.

Minimum Stagger Distances Explained

- Very short stagger distances are structurally weak. When end joints sit too close together, pressure from foot traffic is focused in a small area instead of being spread across the floor.

- Closely aligned joints increase movement and noise. The click system is forced to absorb repeated stress at the same points, which leads to flexing and clicking sounds.

- Most manufacturers define a minimum offset. This distance varies by product, but it is always designed to prevent continuous stress lines from forming across adjacent rows.

- Ignoring minimum stagger distances can void warranties. Floors that fail due to poor joint spacing are often excluded from manufacturer support.

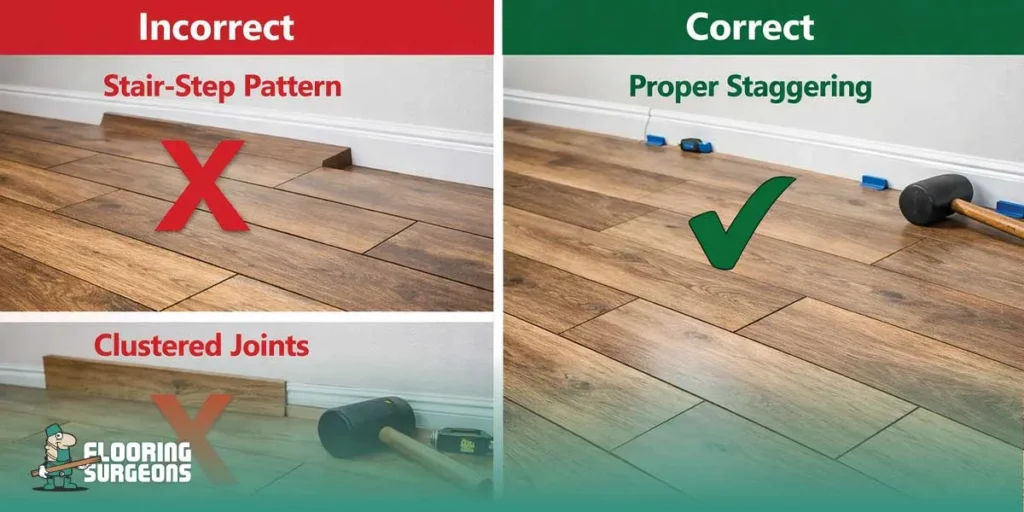

Why Random Is Not the Same as Correct

Standard layouts such as straight plank laminate flooring are designed to work with controlled staggering patterns.

- Random cuts do not guarantee proper spacing. Boards of different lengths can still create repeated short offsets or accidental joint alignment.

- Stair-step patterns are a common mistake. Repeating similar joint positions every few rows concentrates the load instead of distributing it.

- Visually staggered does not mean structurally sound. A floor can look acceptable while still having weak joint alignment underneath.

- Correct staggering follows a controlled layout. Spacing is planned to keep joints consistently separated across the entire installation.

Manufacturer Guidelines vs Common Installation Mistakes

This is where professional installations and failing floors clearly diverge. Manufacturer guidelines exist to protect the structural integrity of the flooring system, while most problems come from ignoring or simplifying those rules during installation.

Why Manufacturer Instructions Matter

- Warranty protection depends on compliance. Most laminate warranties are only valid if joint spacing and staggering rules are followed exactly as specified by the manufacturer.

- Responsibility shifts when failures occur. If a floor develops gaps, noise, or joint failure and the installation does not meet the guidelines, the issue is treated as an installer error, not a product defect.

- Guidelines are based on system behaviour. These instructions are written around how the click system distributes load, not around visual preferences or convenience.

- Ignoring them removes safety margins. Even minor deviations can reduce the floor’s tolerance to movement, temperature change, and daily use.

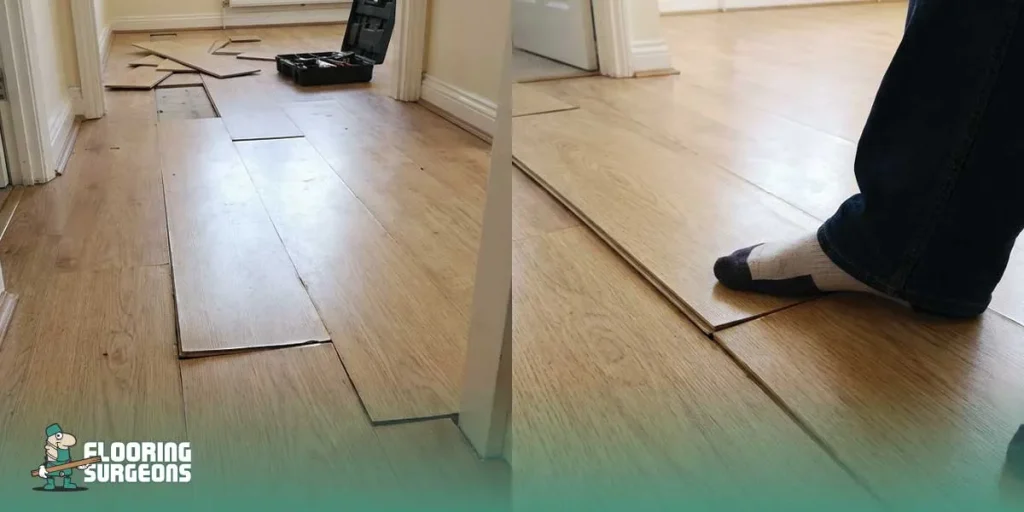

Where DIY Installations Go Wrong

Many DIY installers assume surface-level fixes like painting laminate flooring will solve deeper issues, but cosmetic changes never address structural joint failure.

- Using short cutouts to save material. Repeatedly starting rows with short pieces creates weak joint clusters and concentrates stress in the same areas.

- Repeating joint patterns without planning. Aligning joints at regular intervals, even unintentionally, undermines load distribution across the floor.

- Assuming visual stagger is enough. Floors often look staggered while still failing structurally due to poor joint spacing underneath.

- Treating guidelines as suggestions. Manufacturer instructions are often seen as optional when they are actually the baseline for acceptable performance.

When Staggering Patterns Become a Problem

Not all staggered layouts perform the same, even if they appear neat or evenly spaced. Some patterns that look intentional or decorative work against the structural behaviour of laminate flooring. The table below highlights common staggering approaches that seem acceptable at first glance but often lead to problems over time.

| Stagger Pattern Issue | What It Looks Like in Practice | Why It Causes Problems |

| Overly uniform staggering | Joints repeat at fixed, regular intervals across rows | Creates predictable stress lines that weaken load distribution instead of spreading it naturally |

| Very short stagger distances | End joints sit close together across adjacent rows | Concentrates pressure in small areas, increasing movement, noise, and joint failure |

| Parquet-style imitation patterns | Attempts to copy herringbone or decorative layouts using standard laminate planks | Laminate click systems are not designed for these patterns and lose structural support |

| Visually neat but structurally weak layouts | Floor appears evenly staggered, but joints align beneath the surface | Appearance hides poor joint spacing that leads to long-term failure |

| Repeated starter board lengths | Same cut length used at the start of multiple rows | Forms joint clusters that overload specific sections of the floor |

What to Check Before You Install

Before installing laminate flooring, these checks help determine whether staggering will work as intended or create problems later. Skipping any of them increases the risk of joint failure and costly replacement. Incorrect staggering often leads to full replacement rather than local repairs, including the cost and process of disposing of laminate flooring in the UK.

- Type of click system. Different locking systems handle load and movement differently, which affects how strictly staggering needs to be controlled.

- Manufacturer instructions. Minimum stagger distances and layout rules are defined to protect the integrity of the click system and the warranty.

- Plank length. Shorter boards reduce the margin for error and make poor staggering more likely.

- Room width and layout. Narrow or irregular spaces can force repeated joint patterns if the design is not planned carefully.

- Tolerance for replacement risk. Incorrect staggering often cannot be fixed locally and may require lifting large sections of the floor.

Advice from experienced installers, such as Flooring Surgeons, is often based on real failure patterns rather than visual preferences.